It is a component of Nike’s strategy to integrate sustainability into product design, which would help the design and product development team to make informed decisions that reduce the environmental impact of their products. It is a part of Nike’s broader sustainability initiatives, leveraging data and insights to drive more sustainable material choices and design practices.

It evaluates the environmental impact of various materials based on multiple criteria, including energy use, water use, greenhouse gas emissions, and waste. It gives Each material a score that reflects its overall sustainability performance. Higher scores indicate more sustainable materials.

Key Metrics and Comparative Data

Greenhouse Gas Emissions: Measures the carbon footprint associated with producing a material.

Water Usage: Assesses the volume of water required in the production process.

Energy Consumption: Evaluate the total energy needed for material production.

Chemical Impact: Considers the toxicity and environmental harm of chemicals used in production.

Waste Generation: Looks at the amount of waste produced during the material’s lifecycle.

Few of the key features of the tools that assist the company, for example:

- – Lifecycle Analysis – It to assess the environmental impact of materials from production to disposal. This comprehensive approach ensures that all stages of a material’s life are considered.

- – Benchmarking – compare material with each other and creates comparative data the select the sustainable option.

– Integration with Design Process – The Environmental Apparel Design Tool is integrated into the Nike design process, such that accurate material can be chosen during an early stage of development. It provided real-time feedback

Practical Application

- Material selection – Select materials with lower environmental footprints, promoting the use of recycled, organic, and more sustainable fibres. Example: Nike’s Flyknit technology uses yarn that minimizes waste compared to traditional cut-and-sew methods, significantly reducing material waste.

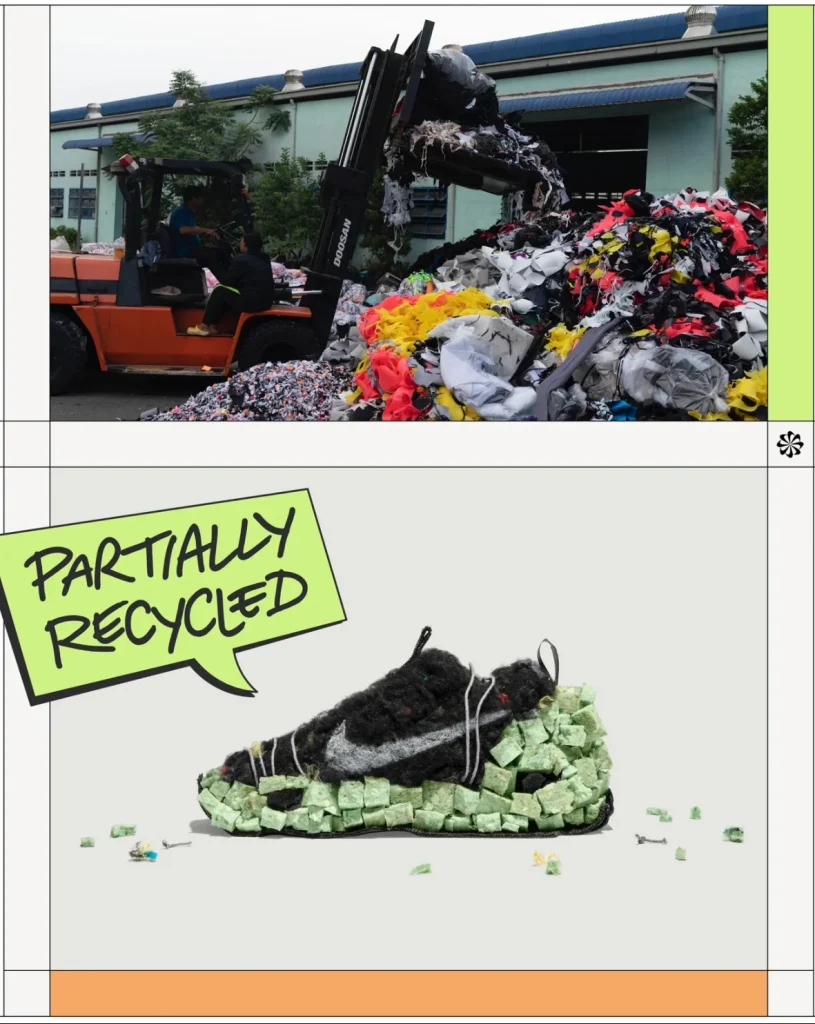

- Product Development – The tool informs the entire product development process, from initial design to final production. By integrating sustainability criteria, Nike can develop products that meet performance and environmental goals. Example: Nike’s Move to Zero initiative, which aims to achieve zero carbon and zero waste, is supported by the insights gained from the Environmental Apparel Design Tool.

- Innovation and Improvement – The tool encourages continuous innovation by identifying areas where environmental impact can be reduced. This leads to the development of new materials and technologies that are both high-performance and sustainable. Example: The Nike Air sole units, which are made with at least 50% recycled materials, are an outcome of such innovation driven by sustainability assessments.

Benefit and Impact

- Reduction in Environmental Footprint – By using the Environmental Apparel Design Tool, Nike has been able to significantly reduce the environmental impact of its products. This includes reduced energy consumption, water use, and greenhouse gas emissions.

- Enhanced Transparency and Accountability – The tool provides a transparent method for measuring and reporting on the sustainability of materials and products. This transparency helps build trust with consumers and stakeholders. Example: Nike’s sustainability reports often highlight the impact of using the Environmental Apparel Design Tool, showcasing improvements in environmental performance.

- Industry Leadership – Nike’s use of the Environmental Apparel Design Tool positions the company as a leader in sustainable design within the apparel industry. This leadership encourages other companies to adopt similar practices, promoting broader industry-wide sustainability.

Example Comparison: Recycled Polyester vs. Virgin Polyester

Greenhouse Gas Emissions:

– Recycled Polyester: Reduces CO2 emissions by up to 30% compared to virgin polyester.

– Virgin Polyester: Higher emissions due to the energy-intensive production process.

Water Usage:

– Recycled Polyester: Significantly lower water usage since it repurposes existing materials.

– Virgin Polyester: High water consumption in the extraction and production phases.

Energy Consumption:

- – Recycled Polyester: Uses less energy as it eliminates the need for raw material extraction.

- – Virgin Polyester: High energy requirement for polymerisation and extrusion processes.

Nike Products developed based on this Tool

- Flyknit Technology

- – Waste Reduction: Flyknit reduces waste by about 60% compared to traditional cut-and-sew methods.

- – Energy and Emissions: The lightweight construction of Flyknit reduces the energy required for transportation, thus lowering CO2 emissions.

- Nike Air Soles

- – Material Usage: Nike Air soles use at least 50% recycled materials.

- – Environmental Impact: This choice reduces waste and lowers the carbon footprint associated with production.

Statistical Outcome and Industry Comparision

- Carbon Footprint Reduction: Nike has reduced its overall carbon footprint by more than 20% over the past decade, outperforming many competitors.

- Water Usage Efficiency: Nike’s initiatives, guided by the EADT, have led to a 30% reduction in water usage per unit of production, compared to a 10-15% reduction in the broader apparel industry.

- Waste Management: Nike has diverted 99% of its footwear manufacturing waste from landfills, significantly higher than the industry average of about 75%.

Leave a Comment