Introduction to Vietnam’s Garment Manufacturing Industry

Vietnam’s garment manufacturing sector is a powerhouse driving the nation’s economy, contributing significantly to GDP and employment. In 2023, authorities raised the minimum wage for workers in Ho Chi Minh City to approximately $190 per month, up from $180 in 2022. This places Vietnam as a global leader in textiles and apparel, second only to China in Asia. With over 2.5 million workers in garment production, the sector not only fuels the export-driven economy but also supports millions of livelihoods. Its rapid growth and strategic importance make it a key player on the global stage.

Challenges Facing Vietnam’s RMG Sector

- Labor-Intensive Processes: Traditional garment manufacturing in Vietnam relies heavily on manual labor, with operators involved in sewing, cutting, and finishing processes. This model is increasingly inefficient, leading to productivity bottlenecks.

- Rising Labor Costs: Vietnam has witnessed a steady increase in labor costs in recent years. In 2023, the minimum wage for workers in Ho Chi Minh City was raised to approximately $190 per month, up from $180 in 2022.

- Global Sustainability and Compliance Pressures: International buyers are increasingly demanding compliance with environmental and social standards. The Vietnamese RMG sector must invest in cleaner technologies and sustainable practices to meet global demands for eco-friendly and ethically produced garments.

- Competitiveness in Productivity and Quality: To remain globally competitive, Vietnamese manufacturers must increase their productivity and ensure the highest standards of quality. The traditional manufacturing methods, though effective in the past, are no longer sufficient to meet the increasingly complex demands of modern global markets.

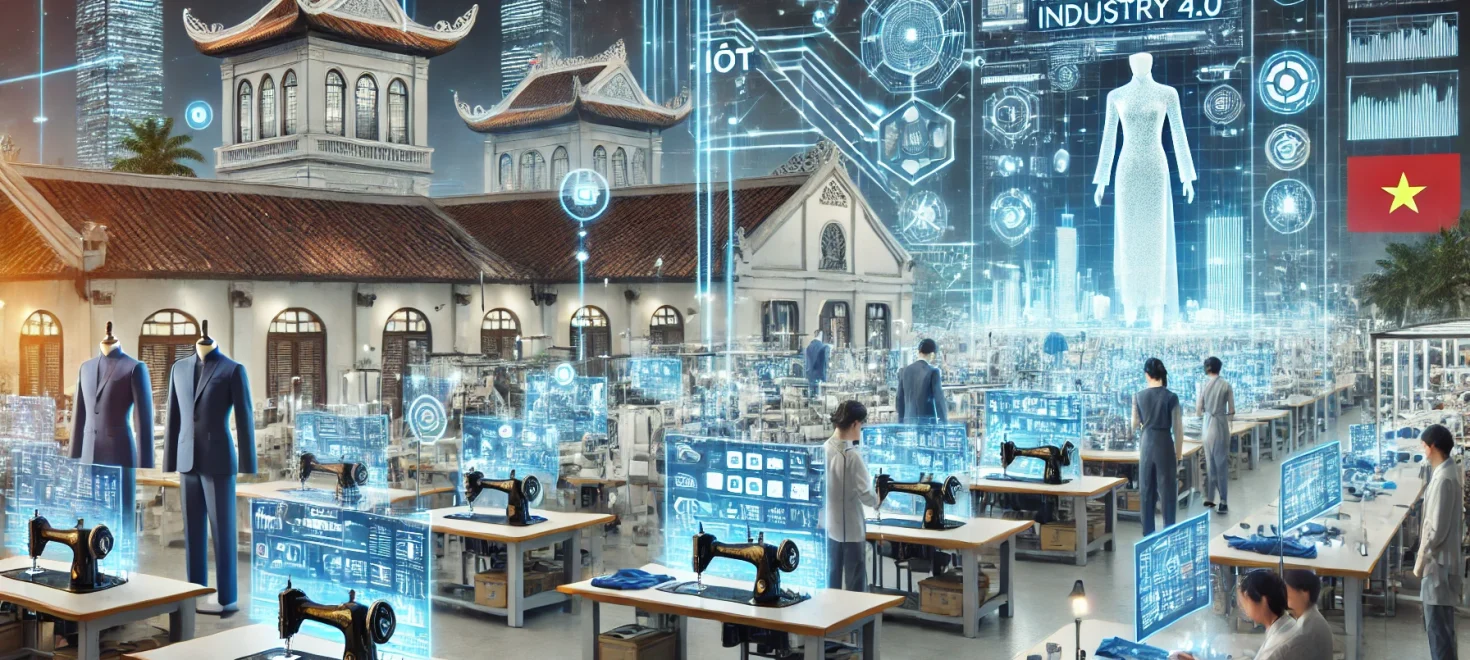

Understanding Industry 4.0 in Manufacturing

Industry 4.0 represents the fourth industrial revolution, driven by the convergence of digital technologies like automation, artificial intelligence (AI), the Internet of Things (IoT), big data analytics, and cloud computing. In apparel manufacturing, Industry 4.0 aims to transform traditional factories into smart factories, where production processes are highly automated, interconnected, and data driven.

- Definition and Key Components: Industry 4.0 integrates advanced technologies into manufacturing to create smarter, more efficient, and sustainable operations. The key components include automation, AI, real-time data collection, cloud computing, and advanced manufacturing systems.

- Industry 4.0 in Apparel Manufacturing: In the context of garment production, Industry 4.0 can revolutionize everything from design to delivery. Real-time data analytics can optimize inventory, streamline the supply chain, and enable predictive maintenance, reducing downtime and improving efficiency.

- Integration of IoT, AI, and Digital Tools in Factories: The IoT connects various devices and machines within a factory, enabling seamless communication and data exchange. AI algorithms can analyze this data to make real-time decisions, while digital tools assist in design, prototyping, and quality control.

Key Technologies Driving Industry 4.0 in RMG

Several technologies are pivotal to transforming the garment industry under Industry 4.0:

- Automation and Robotics: Automated machines and robots are used to perform repetitive tasks such as sewing, cutting, and packaging. Automation significantly reduces human error and increases speed and consistency in production.

- Artificial Intelligence and Predictive Analytics: AI enables manufacturers to analyze vast amounts of data from various sources, including production lines, inventory, and market trends. Predictive analytics can foresee issues such as equipment failure or supply chain disruptions, allowing for preventive measures.

- Digitalization and Cloud-Based Solutions: The digitalization of design and production processes helps improve collaboration and reduces time-to-market. Cloud computing enables seamless integration across different stages of production, from design to logistics, and enhances data accessibility for better decision-making.

- IoT and Real-Time Production Monitoring: IoT-enabled devices monitor production in real-time, providing valuable insights into machine performance, worker productivity, and supply chain status. This data can be accessed remotely, allowing managers to make informed decisions instantly.

- Advanced Manufacturing Techniques: Technologies like 3D knitting, digital printing, and laser cutting are transforming garment manufacturing. These methods offer greater precision, flexibility, and customization compared to traditional techniques.

Benefits of Adopting Industry 4.0 for Vietnam’s Garment Sector

- Enhanced Operational Efficiency and Productivity: Automation and real-time monitoring enable higher throughput and fewer production delays. Automated systems can work 24/7, significantly improving productivity and reducing lead times.

- Cost Optimization and Waste Reduction: Industry 4.0 technologies can optimize material usage, reducing waste and lowering production costs. Predictive maintenance also minimizes the costs associated with unexpected machine breakdowns.

- Improved Supply Chain Transparency: Real-time data provides end-to-end visibility across the supply chain, helping manufacturers better track raw materials, inventory, and shipments. This improves decision-making and reduces stockouts or overstocking.

- Strengthened Compliance and Sustainability Practices: Automated data collection ensures that factories meet environmental and ethical standards by providing accurate reports for compliance. Additionally, AI-driven systems can optimize energy use, helping reduce the environmental footprint.

- Workforce Upskilling and Job Satisfaction: Industry 4.0 involves training workers in new technologies, leading to a more skilled workforce. Employees can take on more rewarding tasks that involve problem-solving and decision-making, enhancing job satisfaction.

Strategic Approach to Industry 4.0 Implementation in Vietnam

- Need Analysis and Feasibility Studies: Before implementation, therefore, manufacturers need to conduct a thorough assessment of their current processes and identify areas where digital transformation can yield the greatest returns.

- Customization for Vietnam’s Unique Manufacturing Needs: Vietnam’s garment sector has distinct characteristics, such as its focus on export and reliance on SMEs. Solutions should be customized to align with the specific needs and scale of individual factories.

- Implementation Roadmap with Clear Milestones: A structured roadmap helps ensure systematic progress in integrating Industry 4.0. Key milestones should include pilot projects, technology selection, and scaling up the implementation process.

- Workforce Training and Change Management: Workers must be trained to handle new technologies, and management must lead the change process effectively to minimize resistance and foster a culture of innovation.

- Monitoring and Continuous Improvement: Post-implementation, manufacturers should continuously monitor outcomes and refine systems for optimal performance, ensuring that Industry 4.0 systems deliver long-term benefits.

Challenges in Implementing Industry 4.0

- Initial Cost Barriers: The upfront investment required for automation, IoT devices, and AI systems can be high, particularly for small and medium enterprises (SMEs). However, the long-term savings and efficiency gains can offset these costs.

- Resistance to Change and Skill Gaps: Workers and management may resist new technologies due to unfamiliarity or fear of job loss. Addressing skill gaps through training programs and creating an environment of continuous learning is crucial.

- Infrastructure and Technology Gaps: Many Vietnamese factories still rely on outdated infrastructure that may not support the latest digital technologies. Investment in modernizing the physical and technological infrastructure is necessary for Industry 4.0 success.

There is a Vietnamese proverb “One tree should not be young / Three trees together make a high mountain”; however, it is also necessary to choose a “tree” to pinch together, in order to have a relationship where all parties Win.

Mr. LE-TIEN-TRUONG

(Chairman of the Board of Directors of Vinatex)

Groyyo Consulting’s Support for Vietnam’s Transition to Smart Manufacturing

4A Yarn Dyeing Limited – A structured training program, including TOT and TOA, equipped individuals with specialized skills for the garment industry. Following a Needs Assessment on efficiency and DHU in the 84-sewing line, improvements in DHU optimization and efficiency were made. Additionally, three LPI training batches with 616 participants drove significant operational improvements. The company achieved a remarkable reduction in lead time, slashing it by over 50%, surpassing the target with a 16% improvement. Efficiency surged by 22.02%, exceeding expectations, while Defects per Hundred Units (DHU) dropped from 32.0 to 13.4. Low-performance issues improved by 23%, far exceeding the initial 15% goal.

Everbright Sweaters Limited– A meticulous selection process identified the best candidates for TOT and TOA programs. Proposals to increase female participation and introduce an incentive scheme were implemented, boosting inclusivity and motivation. Progress included reducing DHU, addressing short shipment issues, and successfully completing two LPI batches, enhancing skills and operational efficiency. Short shipments improved by 0.5%, demonstrating better delivery accuracy. LPI surged by 16%, boosting productivity. In the Knitting and Linking department, reduced DHU minimized material clutter, enhancing traceability and operations.

Trance Home Linen- Process design improvements and layout upgrades were implemented to enhance operational efficiency. Non-value-added processes within the facility were eliminated, streamlining workflows. The introduction of folders and pullers further boosted productivity, while digitization in reporting provided better visibility, enabling more efficient management and decision-making within the factory. Productivity increased by 57% within six months, with a 27% reduction in CPM. Earned minutes per tailor per month rose from 6,206 to 10,661 minutes. Additionally, monthly production numbers surged from 29,713 to 55,743 pieces, reflecting a 103% improvement.

The Future of Vietnam’s Garment Manufacturing with Industry 4.0

Vietnam’s garment industry is at a pivotal juncture. By embracing Industry 4.0, Vietnam can position itself as a global leader in sustainable and high-tech garment manufacturing. The shift to smart factories can enhance Vietnam’s competitiveness in global markets by offering faster production cycles, higher-quality products, and more sustainable practices. Sustainability and digital transformation will become core pillars of Vietnam’s manufacturing future. By integrating digital tools and green technologies, Vietnam’s garment sector can meet the growing demand for eco-friendly and socially responsible apparel.

Conclusion and Call to Action

Vietnam’s garment manufacturing sector stands ready for the transformative benefits of Industry 4.0. The successful integration of digital technologies can help overcome current challenges and unlock new opportunities in global markets. Stakeholders—government bodies, manufacturers, technology providers, and consultants—must collaborate to drive this transformation. By prioritizing smart manufacturing and sustainability, Vietnam can enhance its global position and lead the way in the next industrial revolution in apparel manufacturing.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment