Introduction: Vietnam’s Next Leap in Apparel Manufacturing

Vietnam today stands at the epicenter of global apparel manufacturing. With exports surpassing US$44 billion in 2024, the country has firmly established itself among the world’s leading garment exporters. From the industrial clusters of Ho Chi Minh City to the rapidly expanding zones of Binh Duong and Dong Nai, Vietnam’s appeal has traditionally rested on three pillars: a skilled and cost-efficient workforce, a network of favorable trade agreements such as EVFTA, CPTPP, and RCEP, and a robust, reliable production ecosystem that delivers on time for some of the largest global brands.

Yet, the landscape of apparel manufacturing is undergoing a fundamental transformation. In an industry no longer defined by cost alone, the very metrics of competitiveness are shifting. Global buyers are moving beyond traditional measures of cheap labor and volume capacity. Instead, they now prioritize speed to market, supply chain transparency, sustainability, traceability, and operational flexibility. The demand is not just for garments delivered at scale, but for garments delivered smartly—with real-time visibility, reduced waste, and measurable ESG compliance.

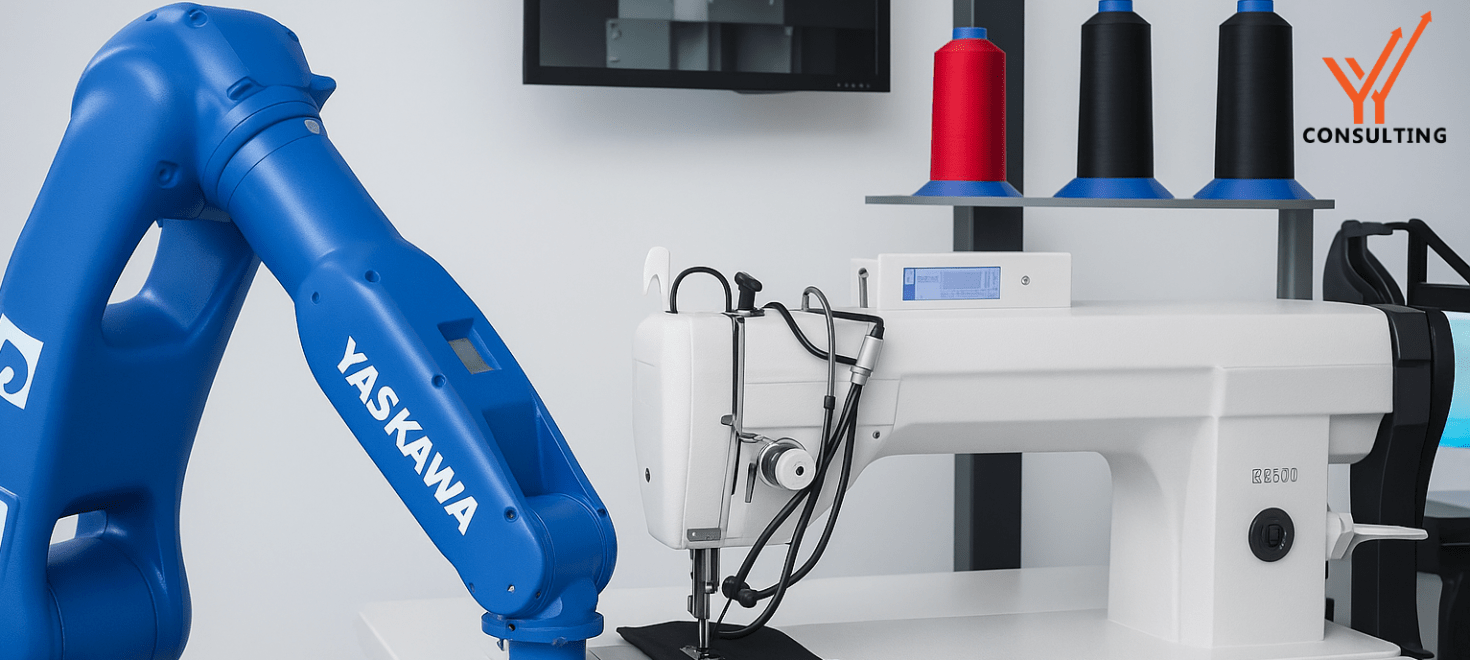

Meeting these expectations demands more than manpower—it requires intelligence at every stage of production. Artificial Intelligence (AI) is becoming Vietnam’s new competitive edge, transforming factories from reactive to predictive and from volume-driven to value-driven. With AI embedded in design, production, and quality, Vietnam is set to evolve from a low-cost supplier into a smart, sustainable, innovation-led apparel hub.

The State of Vietnam’s Apparel Industry Today

The foundation of Vietnam’s success is strong. Access to major trade blocs through CPTPP, EVFTA, and RCEP, combined with political stability, has positioned the country as a preferred sourcing destination. However, challenges are mounting:

- Rising labor costs are narrowing the traditional wage advantage over peers like Bangladesh.

- Buyer compliance pressures—from ESG disclosures to carbon footprint reductions—are increasing.

- Supply chain disruptions have exposed vulnerabilities in planning and responsiveness.

- Intense competition is forcing factories to deliver not only more but also better—faster, leaner, and greener.

Against this backdrop, the role of AI becomes not optional but strategic.

The AI Advantage in Apparel Manufacturing

AI is not about replacing Vietnam’s labor strengths—it is about amplifying them. The core benefits span across the apparel value chain:

- Operational Efficiency

Predictive analytics reduce downtime and optimize line balancing, while AI-enabled scheduling cuts changeover times. - Quality Assurance

Computer vision systems detect fabric flaws or stitching defects in real time, lowering rejection rates and ensuring consistency. - Productivity and Speed

RFID and AI dashboards provide instant visibility into WIP (work-in-progress), empowering supervisors to act on bottlenecks immediately. - Data-Driven Decision-Making

Factory-wide KPIs, tracked via AI-powered dashboards, turn reactive management into proactive planning. - Sustainability

Smarter cutting algorithms minimize fabric waste, while AI-driven energy optimization reduces carbon emissions.

Together, these benefits reshape Vietnam’s proposition from “cost competitive” to “future competitive.”

Case Studies from Vietnam: AI in Action

The AI revolution in Vietnam is no longer theoretical—it is happening on the ground.

Fabric Waste Reduction at Duc Hanh Garment JSC

Fabric is the largest cost in garment production, making even small savings critical. Duc Hanh Garment JSC adopted Coats Digital’s AI-powered fabric optimization tool (FastReactFabric) to improve cutting efficiency. The system uses machine learning to predict consumption accurately and optimize lay planning, reducing reliance on manual estimates.

As a result, the factory cut fabric waste from 1.95% to 1.7% and achieved a 2.2% saving on bill-of-materials costs. Beyond financial gains, the solution also minimized textile waste, supporting sustainability goals and giving production teams real-time visibility to make faster, smarter decisions. This case shows how AI-driven efficiency can deliver both cost savings and environmental benefits in Vietnam’s apparel sector.

AI in Design and Product Development

Traditionally, Vietnam’s strength in apparel manufacturing lay in execution—producing large volumes with consistent quality. Today, however, AI is opening a new dimension of design innovation.

- Generative AI Tools create 3D digital prototypes in hours instead of weeks.

- AI Trend Forecasting predicts shifts in demand, reducing reliance on intuition.

- On-Demand Customization empowers brands to test and launch small-batch collections directly from Vietnam’s factory floors.

Together, these capabilities elevate Vietnam’s role beyond that of a reliable producer, positioning it as a strategic partner in design and innovation for global fashion brands.

AI and Sustainability: From Waste to Circularity

Sustainability is no longer a choice—it is a compliance requirement for brands sourcing from Vietnam. AI is central to this shift:

- Resource Optimization: Smart algorithms reduce fabric waste, water usage, and energy consumption.

- Circular Economy: AI-based sorting helps recycle textiles more efficiently.

- Traceability: Blockchain integrated with AI provides end-to-end visibility of the production cycle.

For global buyers under ESG scrutiny, AI-enabled transparency makes Vietnam a reliable partner in meeting sustainability goals.

The Workforce and AI: Augmentation, Not Replacement

One of the common misconceptions about AI in apparel manufacturing is that it will displace Vietnam’s workforce. In reality, AI serves to augment human capabilities rather than replace them. Operators are moving beyond repetitive manual tasks to take on data-driven supervision, while Industrial Engineers are evolving into digital planners who interpret and act on AI-powered dashboards. Supervisors, too, are being trained in KPI-driven leadership, enhancing accountability and decision-making across the shopfloor. Initiatives like the GEAR program and collaborations between VITAS and global brands are already reskilling workers in areas such as digital literacy, leadership, and sustainability. The vision for Vietnam’s apparel industry is clear: the future factory will not be “lights out,” but rather “skills up”—a workplace where technology empowers people to deliver smarter, more efficient, and more sustainable outcomes.

Challenges in AI Adoption

While promising, AI integration faces hurdles:

- Cost of Implementation: Tier-2 and Tier-3 factories struggle with capital investment.

- Digital Readiness: Fragmentation means not all units have baseline ERP or automation.

- Skills Gap: Managers and workers must adapt to data-centric workflows.

- Data Security & Integration: Seamless sharing between suppliers, brands, and platforms is still evolving.

Acknowledging these challenges ensures that solutions are not just technological but also financial, educational, and strategic.

The Road Ahead: Vietnam’s AI-Driven Apparel Future

Vietnam has a unique opportunity: to leapfrog from being a low-cost exporter to a smart, sustainable manufacturing hub. The road ahead includes:

- Government Policy Support: Incentives for Industry 4.0 investments.

- Brand Partnerships: Global buyers co-investing in AI transformation of their suppliers.

- Consulting Expertise: Independent partners like consulting firms bridging the gap between ambition and execution.

- Regional Positioning: Moving beyond competition with Bangladesh and India—toward standing alongside China as a tech-enabled apparel powerhouse.

The direction is clear: AI is not just a tool, it is the future operating system of Vietnam’s apparel industry.

Conclusion: Stitching the Future with AI

Vietnam’s apparel journey has always been anchored in resilience—navigating trade shifts, global competition, and economic challenges. Now, as AI reshapes the very meaning of manufacturing, the country is once again poised to lead.

The promise of AI is undeniable: faster, smarter, leaner, and more sustainable production. For Vietnam, it isn’t about replacing human expertise but enhancing it with intelligence.

At Groyyo Consulting, we view this not as a mere technology adoption, but as a strategic transformation. Our approach extends beyond frameworks—we partner directly with factories to integrate AI into production planning, quality checks, fabric optimization, line balancing, and live performance monitoring. We guide manufacturers in reimagining their shopfloors as connected digital ecosystems where data, design, and human skill reinforce one another.

We believe, AI when combined with lean systems and workforce development, can convert factories into truly future-ready enterprises. Whether it’s training supervisors to decode AI dashboards or helping leadership harness predictive analytics for buyer demands, we focus on building enduring competitiveness.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment