Executive Summary

Sustainability and green skills are becoming vital for the competitiveness of Bangladesh’s Ready-Made Garment (RMG) sector. The industry, which contributes over 11% to the country’s GDP and accounts for 84% of total exports, faces increasing global pressure to adopt sustainable practices. Key findings highlight critical skill gaps, insufficient regulatory enforcement, and fragmented green initiatives. Strategic recommendations focus on workforce training, technological investments, and policy reforms to foster sustainable growth.

Introduction

The global fashion industry is responsible for 10% of global carbon emissions and 20% of wastewater production. As one of the largest garment exporters, Bangladesh plays a crucial role in mitigating these environmental impacts. Sustainability in the RMG sector not only protects resources but also enhances market access and brand reputation.

- Integrate green skills into apparel manufacturing

- Address workforce competency gaps

- Promote sustainable manufacturing technologies and practices

Data was collected through surveys involving factory owners, workers, policymakers, and industry associations. Case studies of sustainable factories were analysed to draw actionable insights.

Sustainability Challenges in Bangladesh’s Garment Sector

The sector consumes 1,500 billion litres of water annually and generates significant textile waste. Social impacts include health risks from chemical exposure and poor waste management. While regulations such as the Bangladesh Environmental Conservation Act exist, enforcement remains weak. Compliance rates among small and medium enterprises (SMEs) are particularly low.

Defining Green Skills in Apparel Manufacturing

Green skills encompass knowledge and abilities that promote sustainable resource use and reduce environmental impact. They are essential for transitioning to eco-friendly production.

- Energy Management: Reducing energy consumption through efficient machinery and renewable energy adoption.

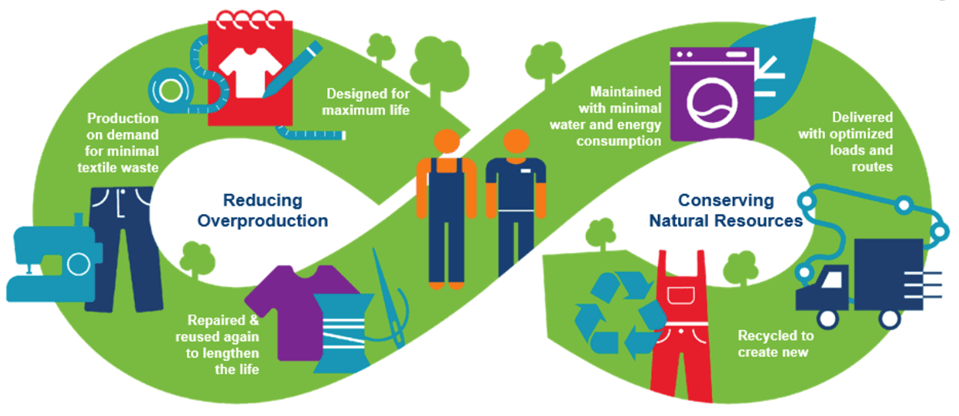

- Resource Efficiency and Waste Minimization: Implementing lean production and circular economy principles.

- Circular Economy and Recycling Practices: Reusing materials and adopting closed-loop systems.

“The industry is now under immense pressure to meet deadlines, and without a swift resolution.

The supply chain could deteriorate even further,”

Analysis of Current Practices and Skill Gaps

Leading factories have adopted solar power, rainwater harvesting, and zero-liquid discharge systems. However, only 10% of factories have fully integrated such measures. Most workers lack formal training in energy management and waste reduction, with only 15% receiving sustainability-specific education. Surveys reveal that 70% of factory managers recognize sustainability as a priority but cite cost and skill shortages as barriers to implementation.

Sustainability Integration in Factory Operations

Replacing traditional machinery with energy-efficient alternatives can reduce electricity consumption by up to 30%. Technologies like effluent treatment plants (ETPs) are underutilized, despite their potential to treat 95% of wastewater. Implementing fabric recycling systems can cut textile waste by 20-30%. Shifting to organic cotton and recycled polyester can significantly lower the carbon footprint.

Framework for Developing Green Skills

Creating a comprehensive green curriculum cantered on energy audits, waste management, and eco-design is vital for building sustainability competencies in the garment industry. Such programs equip workers with the skills to optimize resource use, reduce environmental impact, and innovate eco-friendly production techniques. Collaborations between trade associations and technical institutes enhance training quality and accessibility, ensuring industry-wide impact. Focusing on female workers, who make up 60% of the workforce, promotes inclusivity and amplifies the effectiveness of green skills initiatives, driving broader economic and environmental benefits.

Technological Innovations for Sustainability

Automation minimizes human errors and improves resource utilization, significantly boosting garment factory productivity by up to 20%. By streamlining tasks such as cutting, sewing, and quality control, automated systems enhance accuracy and reduce waste. Solar power installations further drive sustainability, cutting energy expenses by up to 25% and reducing dependence on fossil fuels. Meanwhile, IoT-based technologies enable continuous monitoring of energy and water consumption, providing real-time insights that help factories implement precise control measures, optimize processes, and achieve long-term operational efficiency.

Policy Recommendations and Industry Collaboration

Tax incentives for adopting sustainable technologies reduce the financial burden on garment factories, encouraging investment in energy-efficient machinery and renewable energy systems. Streamlined regulatory processes simplify compliance, enabling faster implementation of green initiatives. Collaboration between government bodies and industry stakeholders fosters innovation by facilitating knowledge transfer, shared expertise, and access to funding opportunities. Drawing lessons from global leaders in green manufacturing provides insights into best practices, enhancing the competitive advantage of Bangladesh’s RMG sector in meeting international sustainability standards and market demands.

Groyyo’s Role in Supporting the Factory : World Victory

A seven-day Need Assessment revealed critical insights into Printing and Embroidery operations, where monthly production reached 200,000 pieces. Key issues included curing inefficiencies, safety concerns, and embroidery’s 18% needle time. Implementing solutions improved printing efficiency by 60.2% and embroidery productivity by 13.6%, supported by 5S inventory practices.

Training for 63 staff (23 women) emphasized sustainability and empowerment. Investments totalling ৳40,557.69 are expected to generate savings of ৳151,530, fostering continuous improvement, reduced waste, and profitability while addressing challenges in female participation and technical skill gaps.

Conclusion and Future Outlook

Sustainability and green skills are vital for the future of Bangladesh’s garment industry, driving eco-friendly innovations and operational efficiency. A strategic, multi-stakeholder approach involving government, industry leaders, and educational institutions can enhance workforce capabilities, reduce environmental impact, and ensure long-term profitability, positioning the sector for global competitiveness and responsible growth.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment