Introduction

In the dynamic world of apparel manufacturing, Bangladesh has emerged as a global powerhouse—particularly in denim and knitwear exports. Yet, as fashion cycles compress, buyers demand traceability, and sustainability becomes non-negotiable, the industry stands at a crucial crossroad. Traditional cost advantages and skilled labor are no longer sufficient. The next phase of competitiveness will be shaped by automation, precision, and intelligent operations.

This article explores how Artificial Intelligence is transforming skill-intensive processes like washing, finishing, sewing, and quality inspection—especially in categories where Bangladesh has built global dominance. It also presents a real-world case study and industry perspectives to illustrate how these shifts are already playing out on the ground.

Rethinking Skill-Intensive Segments: Why Denim and Knitwear Need Tech Intervention

Denim and knitwear production involves complex, high-skill processes—multi-layered stitching, delicate fabrics, intricate washes, and finishing details. While Bangladesh’s workforce is adept at navigating these challenges, human-led processes remain vulnerable to errors, inconsistencies, and fatigue.

At the same time, global brands are demanding:

– Faster turnarounds

– Defect-free, digitally traceable production

– Sustainable processing with lower water and chemical use

This shift calls for a new model—one where technology doesn’t replace labor, but enhances it through automation, standardization, and data-driven insights.

Automated Washing & Finishing: Setting a New Benchmark

Among all finishing categories, denim washing has emerged as a focal point of automation in Bangladesh’s apparel sector. The traditional process—once notorious for excessive water use and chemical discharge—is being radically transformed by smart technologies and environmentally conscious innovation.

Water-Efficient Systems:

Leading washing units in Bangladesh, such as Denimach Washing Ltd. and Ha-Meem Group, have adopted low-liquor ratio machines and closed-loop systems that significantly reduce water and steam consumption. Jeanologia’s e-Flow and ozone-based technologies are now operational in over 100 Bangladeshi denim units, enabling savings of up to 83% in water per pair of jeans.

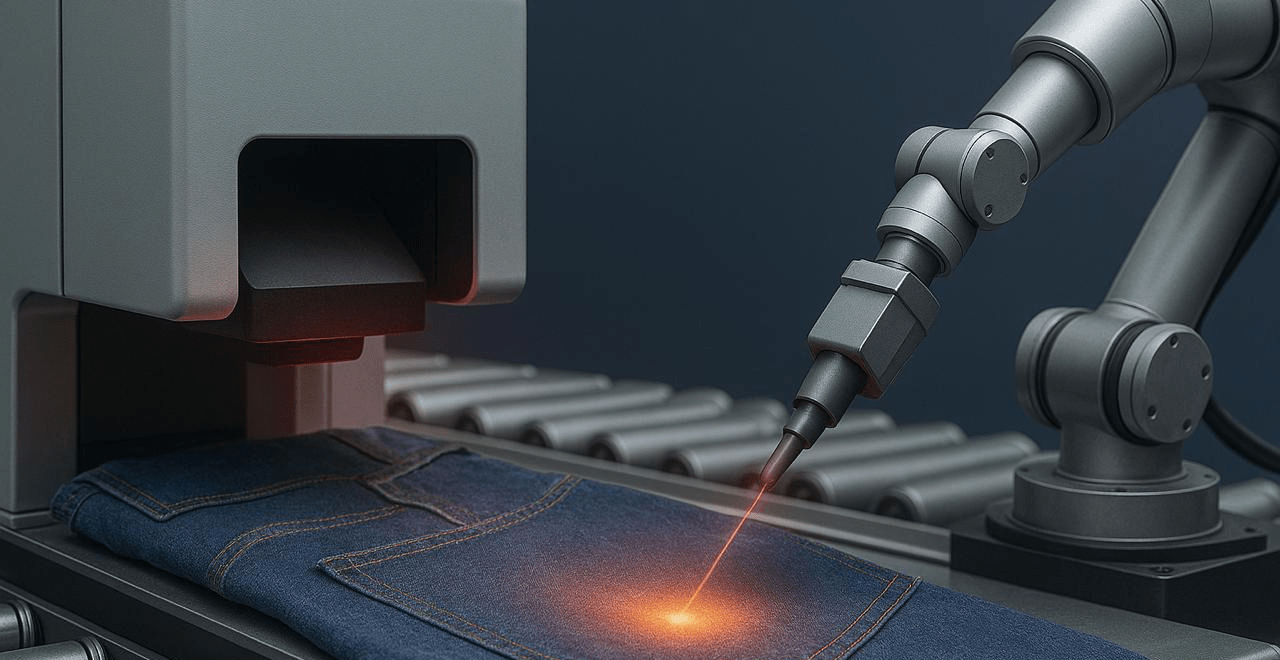

Laser and Digital Sanding:

Manual whiskering and hand scraping have been replaced with laser patterning units, which not only improve operator safety but also deliver repeatable results with zero abrasion-related defects. These machines are pre-programmed to mimic vintage fades and distressed looks without human intervention, enhancing both speed and precision.

AI-Controlled Wash Recipes:

Factories are beginning to implement AI-driven wash recipe optimizers, which analyze historical production data and real-time fabric response to dynamically adjust wash cycles. This eliminates trial-and-error and reduces chemical overuse. Some units are now achieving 30% shorter wash times while maintaining consistent color fastness and hand feel.

Case in Point – Ha-Meem Group (Gazipur):

Their upgraded denim washing plant is a benchmark in sustainable automation. Along with laser finishers and ozone washers, Ha-Meem uses digital controllers for water reuse and energy recovery. The outcome:

-

83% reduction in water per garment

-

30% faster production turnaround

-

Lower chemical inventory and disposal costs

As Bangladesh strengthens its LEED-certified footprint, these washing innovations are aligning perfectly with brand expectations for clean, compliant, and carbon-conscious manufacturing.

Defect Detection Powered by AI Vision Systems

Manual quality checks—though deeply embedded in Bangladesh’s factory culture—are inherently limited by human fatigue and subjectivity. AI is rapidly stepping in to raise the bar.

Real-Time Detection

AI-powered vision systems can now inspect garments in-line for defects like:

– Loose threads

– Stitch gaps

– Shade variation

– Fabric holes or oil spots

Systems like Smartex.ai and QualityAI offer over 95% accuracy, capturing thousands of images per shift and flagging anomalies instantly.

Digital QA Records

Inspection data is logged, analyzed, and displayed via dashboards—giving supervisors full visibility into quality trends by operator, shift, or style.

Rubaiya Rahman, General Manager – Operations, BlueLoop Knitwear Ltd.

“When we implemented AI-driven quality inspection in our knitwear line, defect rates dropped by 40% within the first month. It changed the way our QA team works—less firefighting, more analytics. Buyers love the traceability and consistency.”

Automation in Sewing Lines: From Concept to Capability

Sewing remains the most labor-intensive process in apparel, particularly in knitwear with its stretchy and delicate nature. While full automation in sewing is still a frontier challenge, semi-automated systems are becoming viable in Bangladesh.

Smart Workstations

Machines equipped with sensors now auto-backtack, trim threads, and display visual guidance—reducing dependency on operator memory or repetition.

AI Operator Matching

AI tools can assess operator speed, accuracy, and fatigue to assign them to styles where they’ll be most productive—making line balancing smarter and more efficient.

Smart Cutting, Linking & Knitting: The Factory Floor Evolves

Beyond the needle, other parts of the apparel floor are also getting smarter:

– Auto-cutting systems use AI to optimize pattern placement, reducing waste

– Computerized flat-knitting machines deliver seamless garments with fewer manual interventions

– Linking robots are speeding up sweater assembly while ensuring uniformity

These innovations, especially in the knitwear segment, are helping factories cater to smaller batches and faster style rotations.

Benefits & Bottlenecks: What’s Driving—and Blocking—Automation

Key Benefits:

– 30–40% reduction in rework

– Improved buyer confidence through consistency

– Energy and water savings in finishing

– Enhanced factory floor data and visibility

Key Bottlenecks:

– Upfront investment remains a major barrier, especially for Tier-2 factories

– Technical skill gaps among machine operators and maintenance staff

– Cultural inertia—resistance to shifting from ‘manual mastery’ to ‘machine trust’

The Workforce Equation: Enabling the Human Behind the Machine

A major misconception around automation is that it replaces jobs. In Bangladesh, the more accurate narrative is redeployment and upskilling.

From Tailor to Technician

Automation is creating demand for new roles:

– Laser machine operators

– QA data analysts

– Preventive maintenance engineers

– Digital line supervisors

Reskilling in Action

Several training programs are already responding to this shift:

– BGMEA-SEIP programs now offer machine tech courses

– Groyyo Consulting has rolled out modular training for digital factory transition, focused on upskilling line supervisors and production managers

“Technology should not intimidate our workers—it should empower them. With the right skilling, an operator can move up the value chain, from handling fabric to handling data.”

— Abhishek Yugal, Managing Partner, Groyyo Consulting

Looking Ahead: Bangladesh’s Smart Factory Future

As more buyers shift to near real-time tracking, sustainability-linked contracts, and vendor scoring based on digital maturity, Bangladesh’s factories must accelerate their evolution.

By 2030, expect:

– AI-controlled, demand-driven production scheduling

– Cloud-connected machines sharing live data with brands

– Factory twins—digital replicas that simulate performance and maintenance

– ESG dashboards that combine efficiency metrics with social compliance indicators

Stitching Together Tech, Talent, and Transformation

The transformation of denim and knitwear production in Bangladesh isn’t a speculative future—it’s already underway. Factories that once relied solely on dexterity and volume are now embracing a new identity: smart, agile, and precision-driven.

By integrating AI and robotics thoughtfully—not as replacements but as accelerators—Bangladesh’s apparel industry has the opportunity to set global benchmarks, not just meet them.

This is not about man vs. machine—it’s about building a more intelligent, resilient, and inclusive apparel ecosystem, powered by both.

At Groyyo Consulting, we’re proud to work alongside visionary manufacturers who are redefining what’s possible on the factory floor. The future is not only stitched—it’s intelligently designed.

divyamohan@groyyo.com

Leave a Comment