One technology that has the potential to disrupt the Apparel Manufacturing Industry in the coming years is 3D printing or additive manufacturing.

3D printing in apparel manufacturing involves using specialized machines to create three-dimensional objects by layering material on top of itself, rather than subtracting material like in traditional manufacturing processes. This technology has already made strides in industries like aerospace, automotive, and healthcare, but its application in apparel manufacturing

is still in its early stages.

Here’s how 3D printing could disrupt the Apparel Manufacturing Industry:

- 1. Customization and Personalization: 3D printing allows for

highly customized and personalized clothing items. Customers could potentially

order garments tailored to their specific measurements, style preferences, and

even body shape. - 2. Reduced Waste: Traditional apparel manufacturing results in a significant

amount of material waste. With 3D printing, the process is more precise, and

material is used more efficiently, potentially reducing waste. - 3. Localized Production: 3D printing can enable localized production

centres, reducing the need for large-scale centralized factories and long

supply chains. This could lead to faster production times and reduced transportation

costs. - 4. Rapid Prototyping and Iteration: Designers can quickly

create prototypes and iterate on designs without the need for extensive tooling

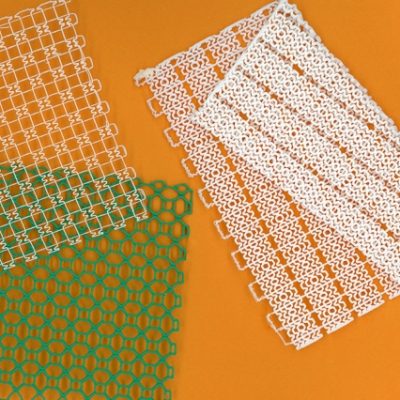

or moulds. This can lead to faster product development cycles. - 5. Complex Geometries and Textures: 3D printing allows for

intricate designs, patterns, and textures that would be challenging or

impossible to create using traditional manufacturing methods. - 6. Sustainable Materials: As the technology advances, it may become

possible to use more sustainable and eco-friendly materials in 3D printing

processes, further reducing the environmental impact of apparel manufacturing. - 7. On-Demand Production: With 3D printing, it becomes feasible to

produce items on-demand, reducing the need for large inventories and

potentially minimizing overproduction. - The development of new materials optimized for 3D printing could lead to advancements in performance, comfort, and durability in clothing.

Amidst the widespread discussions surrounding the potential applications of 3D Printing, there are few organizations/ institutions who have already taken a lead in additive manufacturing in the field of Fashion/ Apparel. For example:

1. National Institute of Fashion Technology (NIFT): In India, NIFT is actively realizing these possibilities through their Same Day Spare Part (SDSP) initiative. Their objective is to swiftly provide or make accessible spare parts within a mere day. Drawing inspiration from the concept of Single Minute Exchange of Dies (SMED), they have aptly named their endeavour Same Day Spare Part (SDSP). The process is as straightforward as perusing an electronic catalogue, where one can effortlessly download and 3D print the required spare part independently, or opt for delivery within a day.

2. Adidas : It has been a pioneer in exploring 3D printing for sportswear. They introduced the Futurecraft 4D shoe, which features a midsole made using 3D printing technology.

3. Nike has also been investing in 3D printing for footwear. They introduced the Nike Vapor Laser Talon, a football cleat with a 3D-printed plate for better traction.

4. Under Armour collaborated with the aerospace company EOS to develop 3D-printed lattice structures for midsoles and cleats in their athletic footwear.

5. New Balance released a 3D-printed running shoe called the Zante Generate, which utilized a 3D-printed midsole.

6. Reebok introduced the Liquid Floatride Run, which featured a 3D-printed liquid midsole.

7. Continuum Fashion is a design studio that has explored 3D-printed fashion, creating garments with intricate geometries that would be impossible with traditional manufacturing methods.

8. Danit Peleg, an Israeli fashion designer, Danit Peleg is known for her collection of 3D-printed clothing that can be produced on desktop 3D printers.

9. Stratasys is a 3D printing company that has worked with various fashion designers and brands to develop 3D-printed fashion pieces. They have also created flexible materials suitable for apparel.

10. Materialise is a Belgian 3D printing company that has collaborated with fashion designers to create unique pieces using their 3D printing technology.

11. Protolabs offers 3D printing services and has worked with fashion and apparel brands to produce prototypes and end-use parts.

12. 3D Systems provides 3D printing solutions across various industries, including fashion and textiles. They have worked on projects involving 3D-printed apparel.

13. Browzwear is a company that provides 3D fashion design software, allowing designers to create virtual prototypes of garments.

The fashion industry needs to transform its ways as the world shifts its prioritisation towards sustainability and circularity, and 3D printing could play a pivotal role in its transformation.

There is obviously an evolution in the way that we are thinking about fashion and clothes manufacturing. New aspects are now taken into account and now it is becoming important to use 3D printing for sustainable and eco-friendly purposes.For instance, textiles are part of the waste problem around the world, that is why a lot of elements of the manufacturing process need to be rethought in order to be more eco-friendly.

Using 3D printing allows to reduce waste, you only need to use the amount of material that is needed to create your project.It is also a way to use some recycled materials for the manufacturing process. Adidas created a 3D printed midsole for one of its sneakers, made with recycled plastic found in the ocean. Creating new materials and using plastic in a more responsible way are new reasons to use 3D printing for fashion companies, and even for big brands such as Adidas.

Additive manufacturing and fashion projects are a great combination. But the link between fashion and 3D printing is quite strong and amazing projects are unveiled quite regularly. Additive manufacturing is evolving, getting even more precise, but also developing new materials and new applications. 3D printing is offering great advantages for the fashion industry, from 3D printed clothes to 3D printed footwear and accessories, the possibilities are endless. In the first place, 3D printing was more used for an artistic touch, but the fashion industry is now developing 3D printed projects of wearable garments.

3D printing provides the fashion industry with a feasible, efficient and sustainable way to produce clothes that mitigates many flaws of the industry’s intense production line. 3D-printed clothes have just begun their journey, and so as more designers discover the incredible opportunity that 3D printers offer, 3D-printed clothes could start appearing more in the mainstream.

In the world of fashion, the call for sustainability is growing louder. A future-forward strategy? Dive into the realm of 3D Printing. This innovative method offers precision unparalleled by traditional methods, enabling exact calculations on materials needed, thus eliminating wasteful overestimations. And while it's relatively new to the fashion scene, other industries have already embraced it, letting go of conventional production techniques.

The fusion of artificial intelligence and the Internet of Things brings about sensors that can fine-tune the application of 3D Printing for clothing design and manufacture. These advancements tackle the challenges of this technique head-on, amping up speed, enhancing consistency, and paving the way for expansive growth. But it doesn’t stop at minimizing waste. The magic of 3D Printing lies in its ability to revolutionize workshops into nimble, cost-effective, and swift production hubs. The fashion of the future is not just stylish, but smart and sustainable.

Additive manufacturing is taking a good shape in Apparel manufacturing especially in Clothing accessories and 3D knitting, many companies have adopted the 3D printing technology for quicker accessories development for prototype as well bulk production, 3D knitting machines are optimizing the material usage, meeting the made to measure requirements, 3D printing is another area where additive manufacturing is applied. Innovation has taken a shape the garments are produced with zero fabric usage, fully flexible for body easy recycling mechanism.

However, it’s important to note that there are still few challenges and limitations to consider. Also, currently 3D printing clothing at scale can be time-consuming and expensive. The technology also needs further advancements in materials and processes to be viable for mass production.

While 3D printing holds great potential to disrupt the Apparel Manufacturing Industry, its widespread adoption and impact will depend on continued technological advancements, cost reduction, and the ability to overcome current limitations.

To get regular updates on news in apparel industry, follow us on linkedin:

Leave a Comment