Introduction

To stay competitive, manufacturing companies need to innovate, improve quality, cut costs, and speed up production. Digitization helps make this possible. Industry 4.0 brings together smart technologies that connect machines, data, and people to create more efficient factories. One of these technologies is called Digital Twin (DT)—a smart way of using real-time data to create a virtual version of a physical production system.

Unlike traditional simulations, Digital Twins update constantly with live data, allowing factories to see what’s happening right now, make better decisions, and even predict problems before they occur.

In the apparel industry, it’s becoming harder to stay profitable. Rising labor costs, lead time delays, the need to produce more customized items have made things challenging. Frequent style changes on the production line reduce efficiency and cause imbalances. It’s also hard to keep production steady when workers’ performance varies.

Other issues like machine breakdowns, training delays, long setup times, and defective products lead to lost time and lower productivity.

Digital Twin technology refers to the creation of a digital replica of a physical object, system, or process. In the context of manufacturing, it allows businesses to visualize operations in real time, simulate outcomes, and make data-driven decisions without disrupting actual workflows. By mirroring every element from machine performance to product flow, digital twins help manufacturers optimize efficiency, quality, and responsiveness.

The journey from Industry 4.0 to Digital Twins has been a natural progression. Industry 4.0 introduced automation, real-time data, and intelligent systems into manufacturing. Digital twins take this further by creating a continuous loop between the physical and digital worlds, where any change in one is reflected in the other. This evolution allows manufacturers not just to monitor but to predict and prevent issues, making production more resilient and adaptive.

For Bangladesh’s RMG sector, the timing couldn’t be better. The country is at a tipping point: global buyers are demanding greater transparency, sustainability is no longer optional, and operational efficiency is critical to remain competitive. With factories already investing in ERP systems, automation, and green certifications, the leap to digital twin technology is both viable and necessary. Embracing this shift could position Bangladesh as a leader in next-generation apparel manufacturing.

Understanding Digital Twins

A digital twin integrates three essential components: a physical asset such as a machine or production line, a virtual model that represents its real-time state and functions, and a data connection that allows continuous interaction between the physical and digital entities. This seamless flow of information enables accurate simulations, monitoring, and predictive analysis.

Depending on the application, digital twins can take different forms. A Product Twin focuses on simulating individual garments or components, helping designers and engineers test designs virtually. A Process Twin models the operations within a specific segment of production, such as a sewing or finishing line. A System Twin, on the other hand, replicates the entire factory environment, offering holistic visibility and control across departments.

The effectiveness of digital twins relies heavily on enabling technologies such as the Internet of Things (IoT), cloud computing, and artificial intelligence. These tools facilitate real-time data collection, storage, and analysis, ensuring that the virtual model remains an accurate and responsive reflection of the physical world. As a result, manufacturers can make informed decisions faster and adapt to dynamic production demands more efficiently.

Brands like Nike and Adidas already use digital twins for virtual sampling, inventory optimization, and predictive maintenance. These technologies help reduce waste, cut costs, and meet environmental compliance. Bangladesh can learn from these models to develop its own roadmap.

Bangladesh RMG Landscape: Readiness and Opportunity

Bangladesh is showing growing readiness for digital twin adoption, thanks to its progressive approach toward modernization and sustainability in apparel manufacturing. Over the past decade, the country has become a global benchmark for green manufacturing, with over 200 LEED-certified garment factories, including some of the highest-rated in the world. These eco-conscious facilities already use advanced ERP systems, automation technologies, and IoT devices, which are essential building blocks for digital twin integration.

Industry bodies such as the BGMEA are actively promoting digitization through capacity-building initiatives, innovation partnerships, and international collaboration. Joint projects with global buyers have accelerated the use of digital tracking systems, automated planning tools, and smart energy management, creating a fertile environment for scaling digital twins. Moreover, digital twin solutions align well with the increasing expectations of international clients for traceability, ethical compliance, and carbon accounting.

The pressure from global sourcing shifts, labor cost dynamics, and the rise of nearshoring has made it imperative for Bangladeshi manufacturers to differentiate through technology. By leveraging digital twins, the country can future-proof its RMG sector, enhance real-time operational visibility, and reduce dependency on manual interventions. With a digitally inclined young workforce, growing policy support, and expanding digital infrastructure, Bangladesh stands at a strategic inflection point—ready to redefine its role in the global apparel value chain.

Applications in RMG Production

Key use cases for digital twins in factories include:

- Virtual sampling: Reducing physical sample costs and timelines

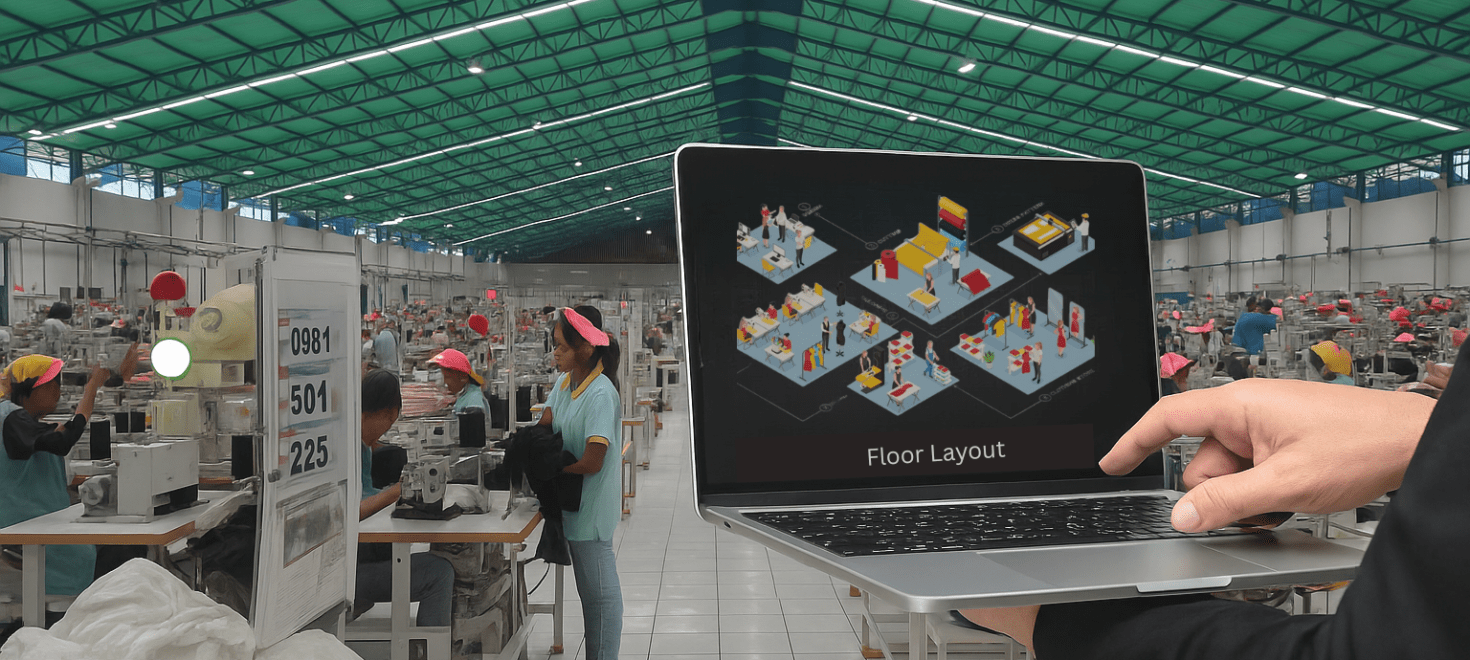

- Production planning: Simulating line layouts to find optimal configurations

- Predictive maintenance: Anticipating equipment failures before they occur

- Energy optimization: Monitoring power usage to reduce environmental impact

- Training and skill development: Using virtual models to train workers without disrupting live production

Benefits and Business Case The implementation of digital twin technology in RMG production offers substantial business benefits and a compelling case for adoption. One of the most significant advantages is the reduction of lead times by 15-20%, allowing manufacturers to respond more quickly to market demands and customer orders. This agility is crucial in an industry where speed often defines competitiveness.

Digital twins also enhance product quality by minimizing defects through real-time monitoring and predictive analytics. By detecting issues before they escalate, manufacturers can uphold higher quality standards and reduce rework or wastage. Moreover, the technology supports better compliance with Environmental, Social, and Governance (ESG) mandates, enabling companies to meet global expectations for ethical and sustainable production practices.

The ability to create transparent, data-driven supply chains is another key benefit. With every stage of production virtually tracked and analyzed, stakeholders gain greater visibility, which aids in traceability, planning, and accountability. Finally, digital twins contribute to significant cost savings by optimizing equipment performance and reducing unplanned downtime through predictive maintenance, while also lowering energy consumption via smart resource management.

Case Study: A Bangladeshi Factory’s Journey One LEED Platinum factory in Gazipur adopted a digital twin for its cutting department. Within six months:

- Downtime reduced by 28%

- Energy savings of 12%

- First-time-right quality improved by 18%

This showcases how even mid-sized units can benefit significantly.

Challenges and Barriers

Despite the promising advantages, the adoption of digital twin technology in Bangladesh’s RMG sector faces several challenges. One of the primary hurdles is the high initial cost of investment in hardware, software, and system integration. Many small and mid-sized factories operate on thin margins and may find it difficult to justify the upfront capital expenditure.

Another significant barrier is the shortage of skilled professionals who can design, implement, and manage digital twin solutions. The transition to digital manufacturing requires a workforce proficient in data analytics, simulation modeling, and system management—skills that are currently limited in the traditional garment sector.

Furthermore, a large number of factories still depend on legacy systems that are not easily compatible with modern digital infrastructures. Upgrading these systems can be time-consuming and expensive, particularly without adequate technical support or standardized frameworks.

Concerns around data privacy and cybersecurity also pose risks. As digital twins rely heavily on real-time data and cloud-based networks, ensuring secure data transfer and protecting sensitive operational information is essential. Manufacturers need clear protocols and robust safeguards to manage these risks effectively.

Implementation Roadmap

For Bangladesh to successfully implement digital twin technology, a strategic and phased approach is essential. The first step should be initiating pilot programs in digitally mature factories that already possess basic automation and data infrastructure. These pilot sites can serve as learning hubs and demonstration models for broader industry adoption.

Next, collaboration with technology providers, research institutions, and global apparel brands will be crucial. Such partnerships can facilitate knowledge exchange, co-development of scalable tools, and easier access to affordable solutions tailored for local manufacturing contexts.

Equally important is workforce development. Upskilling current employees and training new professionals in digital literacy, data analytics, and simulation-based planning must become a national priority. Institutions offering textile education and industrial training should revise their curricula to align with these emerging technological needs.

Finally, government support can act as a catalyst. Financial incentives, such as grants or tax rebates for digital investments, and policy initiatives promoting Industry 4.0 adoption will help accelerate the transition. A clear, coordinated roadmap backed by policy, funding, and industry participation will be key to mainstreaming digital twins in Bangladesh’s RMG sector.

Future Outlook

Looking ahead, digital twin technology is set to become a central pillar in the evolution of smart apparel manufacturing. As concepts like “dark factories”—fully automated, human-free production units—move from vision to reality, digital twins will provide the critical framework for continuous monitoring, self-regulation, and autonomous decision-making. Furthermore, in an era of increasing consumer consciousness, the integration of digital twins with blockchain will enable end-to-end traceability, helping brands demonstrate transparency and build trust.

Digital twins also support the shift toward circularity. By capturing product lifecycle data, they make it easier to plan for reuse, recycling, and material recovery. Combined with on-demand manufacturing and mass customization trends, digital twins will allow manufacturers to produce efficiently with minimal waste. For Bangladesh, this means building a resilient, tech-enabled, and sustainable RMG ecosystem—one that responds proactively to market shifts while setting benchmarks for responsible production.

The transformation of Bangladesh’s RMG sector is not a question of if, but when. Digital twins offer a proven pathway to smarter operations, greater visibility, and sustainable growth. With its strong manufacturing base, growing digital infrastructure, and an increasingly skilled workforce, Bangladesh is well-positioned to lead this change. However, success will require a collective commitment—by factories, technology providers, academia, and policymakers—to invest, learn, and adapt together. If executed well, digital twins won’t just enhance production—they’ll redefine the very future of apparel manufacturing in Bangladesh.

In this new era of smart manufacturing, the transition to digital twins represents more than a technological upgrade; it’s a cultural shift toward real-time decision-making, predictive control, and process excellence.

At Groyyo Consulting, we understand that adopting digital twins is not a plug-and-play solution — it requires vision, capability-building, and aligned execution. That’s why we go beyond being just a technology partner. We work alongside factories to design the right systems, develop future-ready talent, and deliver actionable insights that enable manufacturers to set new industry benchmarks.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment