For decades, the narrative around Bangladesh’s apparel industry was clear-cut — a nation powering global fashion with needle-sharp focus on cost. The factories never slept. Day and night, sewing machines hummed in synchrony. Buyers flocked to Dhaka not for innovation or environmental credentials — but for price.

Bangladesh was the world’s ready-made garment (RMG) engine.

Fast, scalable, and cost-effective.

But the world changed.

Suddenly, fashion wasn’t just about trend cycles and supply chains.

It was about ethics, transparency, and climate accountability.

Consumers started asking uncomfortable questions:

-

Who made my clothes?

-

How were they made?

-

At what cost to people and the planet?

And in that defining moment, Bangladesh made a bold decision — not to defend the old story, but to rewrite it entirely.

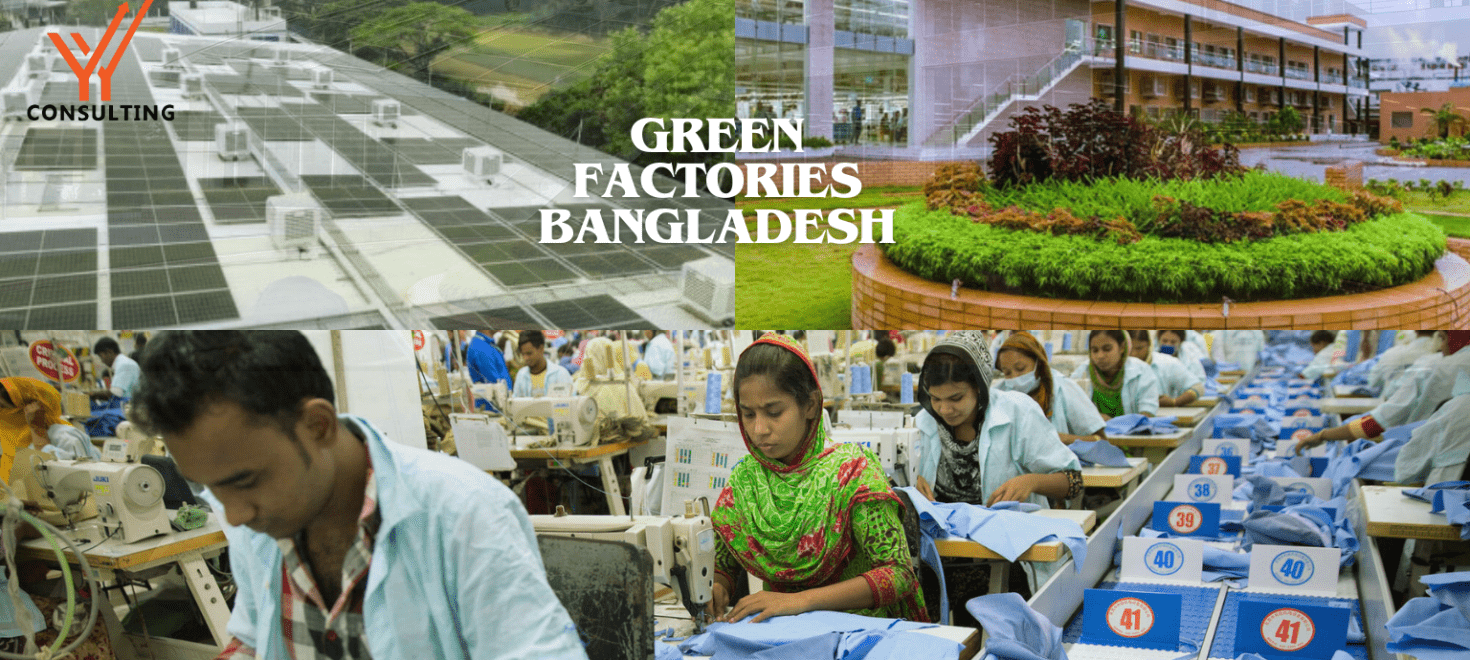

The Green Revolution: Bangladesh’s LEED Leadership

When it comes to sustainable garment manufacturing, Bangladesh is no longer just catching up — it’s leading.

As of today, the country is home to over 200 LEED-certified green garment factories — the highest concentration of green factories in the world. Over 50 of these are Platinum-rated — the highest level of environmental excellence recognized by the U.S. Green Building Council.

From the industrial alleys of Gazipur to the coastal corridors of Chattogram, a quiet transformation is reshaping Bangladesh’s identity — one solar panel, one rainwater harvesting unit, and one ergonomic workstation at a time

To put it simply:

More green factories are born in Bangladesh than anywhere else on Earth. This isn’t just a response to pressure from buyers — it’s a reimagination of purpose.

What’s Fueling the Green Shift?

This shift didn’t happen by accident. It was the result of a perfect storm of intent, insight, and initiative.

1. Brands Raised the Bar

Global giants like H&M, PVH, and Inditex revised their sourcing strategies, demanding higher environmental and social standards from their supplier base.

2. Government Support Amplified Change

Forward-thinking policies, green financing schemes, and support for fast-tracked certifications helped catalyze change at scale.

3. A New Breed of Entrepreneurs Emerged

Young, ambitious factory owners in Bangladesh began to see that green wasn’t just good for PR — it was good business. They recognized that sustainability was the new language of global commerce.

Inside a Green Factory

Step into a modern LEED Platinum-certified garment factory in Bangladesh, and you’ll feel the difference almost instantly.

-

Skylights and smart lighting reduce electricity usage by up to 60%.

-

Water is captured from rainfall and reused after purification.

-

Advanced HVAC systems regulate temperature for both machine and human comfort.

-

Waste is not discarded — it’s recycled, repurposed, and tracked digitally.

-

Workers aren’t crammed into dim halls — they work in spaces with light, air, and dignity.

Champions of Change: Stories That Inspire

The Platinum Pioneer — Gazipur

A once-conventional factory in Gazipur, built with tin walls and flickering lights, decided to change its destiny. Partnering with sustainability consultants, it integrated solar energy, digital utility monitoring, and water-efficient dyeing systems. It became one of Bangladesh’s first Platinum LEED-certified plants. Today, its biggest buyers aren’t just sending orders — they’re showcasing the factory in ESG reports.

The Small Giant — Narayanganj

A medium-sized unit, long overlooked in the sourcing game, committed to green principles — without the advantage of massive capital. It focused on waste segregation, modular layouts, and efficient utilities. Within two years, it was Gold certified. The factory now supplies premium European brands and commands better margins per piece — proving size isn’t the only metric for success.

Sustainability as a Business Strategy

Let’s be clear — going green wasn’t just a moral pivot. It was a strategic one.

Factories that embraced sustainability early reported:

-

Higher buyer retention

-

Improved unit pricing (green premiums)

-

Longer-term contracts

-

Global campaign visibility as “ethical supply partners”

Challenges on the Green Journey

Of course, this journey hasn’t been easy.

-

Smaller factories feared high capex investment.

-

Resistance to new SOPs was common on shop floors.

-

Technical know-how for sustainability reporting and certification was limited.

But the momentum has been relentless.

The Future: Bangladesh as the Blueprint for Sustainable Fashion

As the fashion world accelerates toward carbon neutrality and UN SDG alignment, Bangladesh is no longer the “low-cost option.”

It is now the global benchmark.

Already aligning with the upcoming EU Green Deal requirements and net-zero goals, Bangladesh is poised to become the preferred partner for sustainable sourcing. The scale is ready. The mindset is maturing. And the infrastructure is rapidly transforming.

From Threads to Triumph

Once known for volume and affordability, Bangladesh is now stitching together something far more enduring — a legacy of responsibility.

This isn’t just a new chapter.

It’s a new story — of resilience, reinvention, and remarkable leadership.

Groyyo Consulting, as a strategic guide, continues to stand beside these pioneers — not just advising factories, but building futures where fashion respects both people and the planet.

Because the future of fashion will be defined not by trends,

But by trust.

Not by how fast we make,

But by how responsibly we create.

And Bangladesh — powered by purpose, guided by values, and supported by bold partners — is already leading that future, one stitch at a time.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment