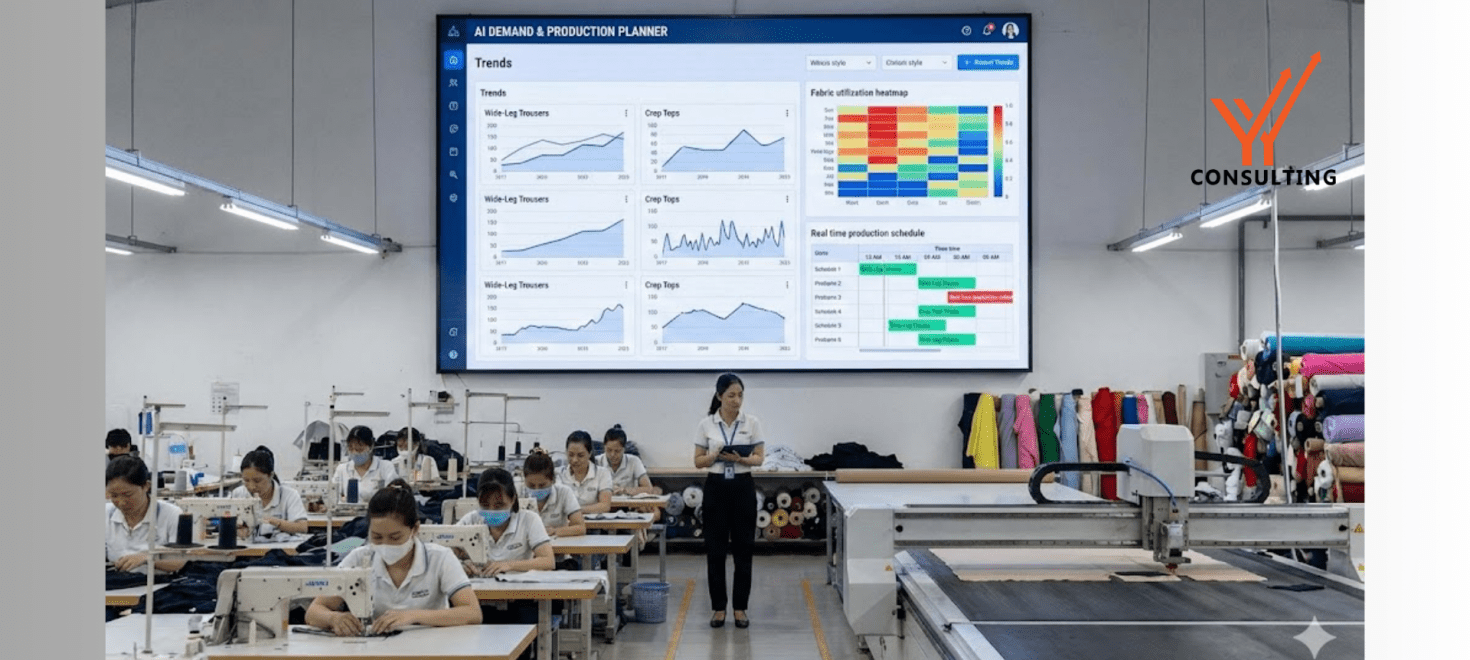

As another busy week begins in Ho Chi Minh City, a merchandiser sits down at her workstation and immediately notices something different. Instead of wrestling with overflowing Excel sheets or scrolling through a cluttered trail of overnight messages, she is greeted by a dashboard that has already done the heavy lifting for her. It outlines upcoming material needs, pinpoints the exact moments when capacity will be under pressure, and flags styles that may slip due to production variability. Although the machines on the sewing floor have yet to start humming, the system already has a near-complete picture of how the week is expected to unfold—often with greater accuracy than any individual planner could achieve on their own.

This is the kind of quiet transformation that is beginning to define Vietnam’s apparel sector. While many factories across Asia still depend heavily on instinct, experience, and manual spreadsheet-driven planning, Vietnamese manufacturers have started to embed artificial intelligence into their daily decision-making. As a result, they are moving from reactive management to a new era of predictive, confidence-driven planning. In a global industry where lead times are tightening and efficiency expectations are rising, Vietnam’s early adoption of AI-enabled planning is becoming a powerful competitive differentiator.

The Old Way of Planning: Familiar, Experienced, but Ultimately Limited

For decades, production planning in apparel manufacturing has relied on a blend of experience, intuition, and spreadsheets. Seasoned planners often pride themselves on knowing how many days a style will take or predicting how a line will behave during peak season. However, apparel manufacturing is full of hidden variables—changing SMVs, fluctuating operator skill levels, inconsistent machine performance, unexpected absenteeism, and volatile buyer requests. As a result, even the most experienced planners often find themselves reacting to surprises late in the cycle.

Traditional planning systems also depend heavily on manual data entry, which makes them slow, error-prone, and incapable of processing large volumes of historical data. When forecasting capacity or planning future orders, many factories still rely on simplified averages or outdated performance benchmarks. This creates incomplete visibility, leaving planners unaware of approaching bottlenecks until they have already caused delays. For years, such uncertainty was considered inevitable in garment production. Factories believed that firefighting was simply part of the business.

But Vietnam, with its strong industrial engineering culture and rapidly modernising manufacturing landscape, has begun to challenge this notion by embracing AI-enabled forecasting tools that uncover patterns humans simply cannot process at scale.

The Vietnam Advantage: Data Discipline Meets Digital Maturity

Vietnam’s factories entered the AI era with several inherent strengths. Many Vietnamese manufacturers already maintain detailed performance data, including SMV histories, hourly efficiency reports, operator skill matrices, machine maintenance records, and line output curves. This culture of measurement, driven by a strong industrial engineering backbone, has created a rich foundation for AI systems to learn from.

AI thrives on pattern recognition. When fed with years of output variations, operator learning curves, style complexity attributes, machine downtime histories, material arrival patterns, and real-time production signals, AI generates forecasts that are far more accurate than any manual method. It identifies correlations that planners may sense instinctively but cannot quantify. It highlights emerging risks before they become visible to the human eye. It transforms planning from guesswork into science.

For Vietnamese factories, the biggest advantage is not just that AI makes planning faster; it is that AI makes planning significantly more accurate. In a sector where a delay of one or two days can threaten an entire buyer relationship, accuracy becomes a strategic currency.

Why AI-Enabled Planning Works So Well in Vietnam

Vietnam’s unique manufacturing ecosystem makes it fertile ground for AI-driven forecasting.

- Strong IE Culture

Factories already love data.

SMVs, efficiency curves, operator matrices—Vietnamese plants are disciplined about measurement.

AI thrives on this maturity.

- High Product Complexity

From jackets to performance wear, Vietnam handles categories with multiple components and variable SMVs.

High complexity = high forecasting payoff.

- Leadership That Wants Predictability

Vietnamese factory leaders no longer celebrate heroic firefighting.

They celebrate predictability—AI makes that possible.

- Digital-savvy workforce

Young planners and merchandisers are comfortable with dashboards and decision-support tools.

Adoption is fast, resistance is low.

For Vietnamese factories, the biggest advantage is not just that AI makes planning faster; it is that AI makes planning significantly more accurate. In a sector where a delay of one or two days can threaten an entire buyer relationship, accuracy becomes a strategic currency.

Why AI Works Especially Well in Vietnam

Vietnam’s apparel industry sits at a unique crossroads of strong industrial engineering discipline and rapid digital adoption, creating ideal conditions for AI to thrive. Factories already rely heavily on data—SMVs, efficiency curves, and skill matrices—so AI integrates naturally into existing systems. The country’s product mix, which includes complex categories like outerwear and performance wear, increases planning variability and makes predictive forecasting even more valuable. Leadership teams are also shifting from reactive management to a mindset that values predictability and control. Combined with a digitally savvy workforce entering planning and merchandising roles, Vietnam offers a fertile environment for AI-driven transformation.

AI Does Not Replace Planners—It Elevates Them

AI doesn’t eliminate the need for planners; it elevates their work. Instead of spending hours updating spreadsheets or chasing data inconsistencies, planners gain real-time visibility and predictive insights that help them make smarter decisions. AI highlights risks weeks in advance, simulates capacity scenarios, and identifies potential bottlenecks before they occur. This allows planners to focus on high-value tasks such as coordinating across departments, communicating with buyers, negotiating realistic timelines, and ensuring smoother execution across the production chain.

Real Example: Vietnam’s AI Manufacturing Push

TNG Investment and Trading JSC, one of Vietnam’s leading garment exporters, has partnered with a Korean AI technology firm to introduce smart production planning and energy-usage optimization across its textile mills. The collaboration allows TNG to analyse real-time machine data, predict production loads more accurately, and balance capacity with far greater precision. By combining operational analytics with AI-driven forecasting, the company is not only improving planning accuracy but also reducing energy waste—demonstrating how digital transformation is reshaping Vietnam’s competitiveness in apparel manufacturing.

The Competitive Outcome: Vietnamese Factories Deliver Better Because They Plan Better

Factories in Vietnam that have embraced AI-enabled planning are already reporting measurable business outcomes. Many have achieved higher on-time delivery performance because they are evaluating risk earlier and managing capacity proactively. Others are identifying hidden capacity gaps that allow them to take on additional orders during peak seasons without violating commitments. Some factories have reduced internal cost by lowering last-minute overtime, emergency outsourcing, and excessive buffer stock.

AI also helps reduce planning errors caused by incomplete data, miscommunication, or unpredictable fluctuations. When planning becomes more accurate, every downstream activity—from cutting to sewing to finishing—benefits from the stability it creates. In a highly competitive regional landscape, these advantages compound over time, enabling Vietnamese factories to outperform peers in both reliability and responsiveness.

The Future of AI Planning: Forecasting That Feels Almost Magical

Looking ahead, the possibilities for AI planning in apparel manufacturing are vast. Imagine a scenario in which a new tech pack is uploaded and the system instantly evaluates the style’s complexity, estimates the likely efficiency curve, identifies which operators will learn the style quickly, and highlights potential quality risks. AI could run hundreds of simulated production scenarios within seconds, offering planners recommendations that account for real constraints. It could even guide preventive maintenance scheduling by predicting when machines will cause downtime.

Vietnam is moving steadily toward this future. Its factories are increasingly integrating planning systems with production-floor data, ERP solutions, and operator skill matrices, creating a connected ecosystem capable of learning continuously. As these systems mature, forecasting will feel less like planning and more like intelligent navigation.

Conclusion: The Factories That Forecast Better Are the Factories That Win

In an industry long defined by unpredictability, Vietnamese manufacturers are demonstrating that uncertainty can be engineered out of the planning process. By adopting AI-enabled solutions, they are moving from reactive management to anticipatory control, transforming the rhythm of their operations. AI does not replace human expertise; it enhances it by providing planners with the precision, clarity, and foresight that modern manufacturing demands.

For factories seeking to adopt these advanced planning capabilities, Groyyo Consulting provides the strategic and technological guidance needed to make the transition seamless. Through targeted digital interventions, AI-driven planning frameworks, and practical on-ground operational support, Groyyo Consulting helps manufacturers unlock the full competitive advantage of intelligent forecasting. By empowering teams with the tools to anticipate challenges before they arise, Groyyo Consulting enables factories not just to keep pace with the future—but to stay ahead of it.

Divya Mohan

General Manager (International Business)

divyamohan@groyyo.com

Leave a Comment